Productos Populares

-

¡Oferta!

Botín Mujer | Botin dalia apricot | Hispanitas

€ 183.46€ 78.26 Seleccionar opciones -

¡Oferta!

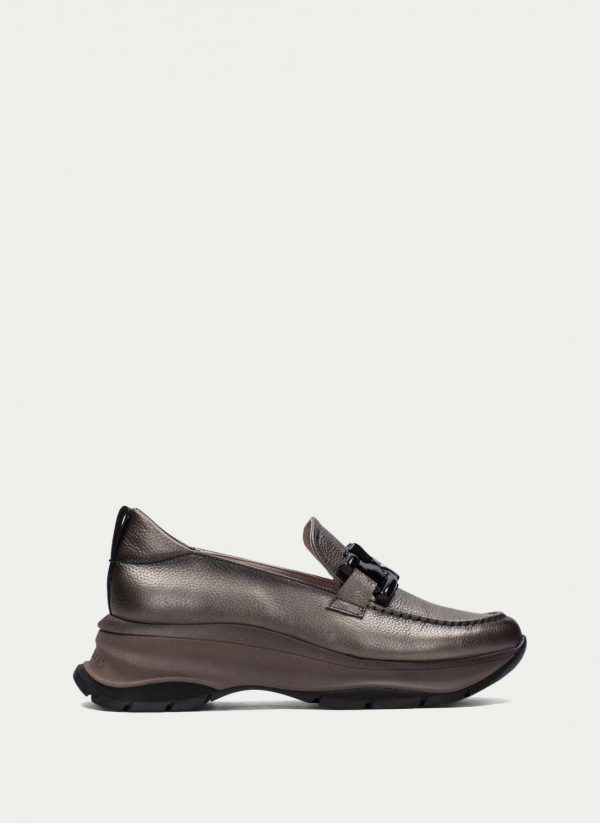

Mocasín Sport Mujer | Mocasin Sport alaska plomo | Hispanitas

€ 112.93€ 68.25 Seleccionar opciones -

¡Oferta!

Salones Mujer | Salon dalia marfil | Hispanitas

€ 142.14€ 66.43 Seleccionar opciones -

¡Oferta!

Mocasines Mujer | Mocasin charlize forest | Hispanitas

€ 120.12€ 81.90 Seleccionar opciones

Productos Destacados

-

¡Oferta!

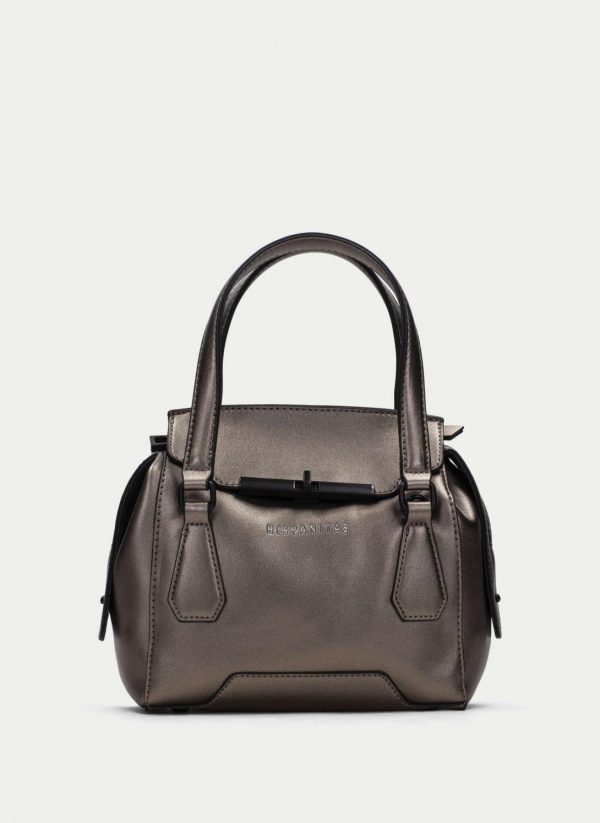

Top Handle Mujer | Top Handle plomo | Hispanitas

€ 135.95€ 77.35 Añadir al carrito -

¡Oferta!

Botín Mujer | Botin tokio cuero | Hispanitas

€ 138.32€ 74.62 Seleccionar opciones -

¡Oferta!

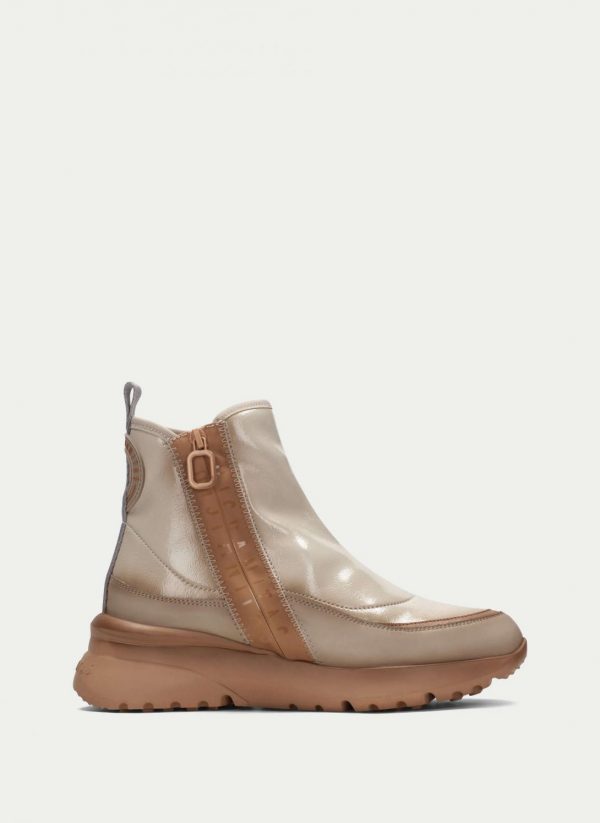

Botín Sport Mujer | Botin sport polinesia marfil | Hispanitas

€ 131.04€ 74.62 Seleccionar opciones -

¡Oferta!

Salones Mujer | Salon monaco gobi | Hispanitas

€ 114.48€ 69.16 Seleccionar opciones